Information On River Tables And Epoxy Resin From Chagrin Valley Custom Furniture

-

Are River Tables Strong?

-

Well built epoxy resin river tables made by CVCF with sturdy natural live edge hardwood slabs are extremely durable and can seat 8, 10, 12 or more people. The surfaces of river table tops made by CVCF, are beautiful, strong and virtually impenetrable. The custom metal river table legs and bases handcrafted by CVCF will last for generations without maintenance.

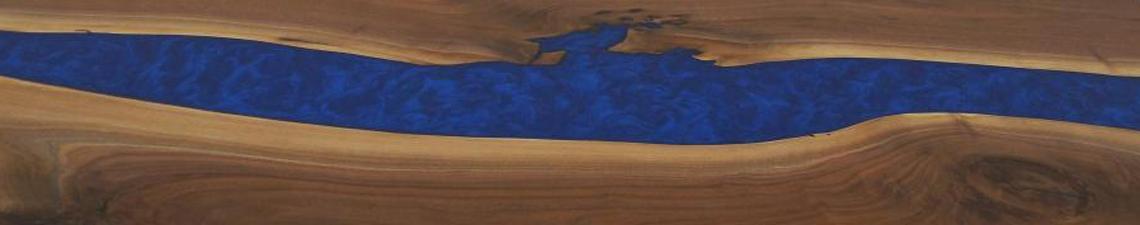

Epoxy Resin River Table Top Wood Options Are Endless | A Few Live Edge Wood Slab Epoxy River Dining Table Tops Are Shown Below

CVCF only makes custom epoxy resin furniture out of solid wood slabs—generally with the live edge included. The woods below are the ones we find make the best river tables. A dark river with light wood is awesome. A light river with dark wood is even more awesome. You can’t go wrong! Our customers can pick out the exact slab they want when we take them into our wood warehouse or supplier’s lumberyard via video technology.

Our workshop is in the Chagrin Valley of Ohio, an area that supports the growth of hundreds of wood species on sustainable farms. Give us a call at 440-591-5511 and Sheldon will help you with your wood selection.

At CVCF, we make our own custom metal legs, often based on our customer’s own table leg concepts. Get inspired by some of our designs, or order one you see below. You can send us a photo or drawing of a leg you want us to reproduce. Then tell us what kind of tabletop you want. At CVCF, we cover all the bases (and legs)!

CVCF Artisans Layer And Embed Anything Into Epoxy Resin Rivers For Custom Made Live Edge Dining And Coffee Tables

-

CVCF Clients Send Us Rocks, Fish, LED Lights, Stones, Bullets, Glass And All Kinds Of Memorabilia That They Want In Their River

-

CNC Carved Company Logos And Family Names Are Filled With Any Color Epoxy Resin

-

Common Requests From Customers For Custom Built River Tables Are Show Below

Chagrin Valley Custom Furniture has become more creative in our execution of river table designs by adding decorative elements in the resin before it cures. Taking the “river” concept to its logical conclusion, our builders can make tables embedded with smooth stones, rocks, shells, crystals and more that line the bottom of the resin, adding a premium rustic, outdoorsy flair to an already stunning concept.

Chagrin Valley Custom Furniture sells and handcrafts completely custom epoxy resin and wood furniture, river coffee tables and wood and resin dining tables. CVCF craftspeople make the highest quality epoxy resin river tables in the U.S. Buy custom furniture for sale near you or online from Chagrin Valley Custom Furniture.

Our woodworkers and resin artists create one-of-a-kind resin art tables, bar tops, epoxy resin and wood kitchen island tops, countertops, table tops and epoxy resin ocean tables.

We make epoxy resin and wood conference tables, custom river tables, ocean coffee tables and epoxy resin and wood waterfall tables for families, homes, cottages, restaurants, business offices, hotels, sports bars and corporate customers throughout the United States.

The Chagrin Valley process is different from other custom furniture makers (builders) because we only make true custom furniture. That means you don’t go online to order and pay at the start of the process. With CVCF, you are part of the custom furniture-making process every step of the way as together we create a completely new, one-of-a-kind piece of epoxy resin furniture, specific to your unique needs and desires.

You give us your design idea, choose the epoxy color, wood slab, make tweaks in the design, all remotely through video technology. You can even have an emblem or your company logo machined into the wood and filled with epoxy, or embed items in the epoxy such as school and college logos, rocks, crystals, and other sentimental memorabilia.

We harvest our wood sustainably, often under the direction of the U.S. Forest Service. This ensures the long term health of the forest. We spend up to 2 years removing moisture from the logs before starting to work with them. This helps prevent warping and cracking of the wood.

Our 6,000 sq. ft. workshop is fully equipped to handle all the challenges of making a beautiful epoxy resin river table, which includes a temperature controlled, clean spray room for a smoother, scratch-resistant coat. We also offer a large variety of metal and wood legs, plus you can design your own legs if you wish.

Our furnishings include custom epoxy resin river tables, epoxy resin river beds and headboards, epoxy resin desks, epoxy resin wall art, rustic to modern farmhouse tables, barn doors, benches, countertops, shelves and so much more.

Prices for our conference tables are based on such factors as size, wood species, live edge/not live edge, conference table components, epoxy resin, engraved company names, engraved logos, embedded objects in epoxy resin rivers, etc.

Prices for our solid wood and live edge conference tables start at about $4,500, average about $9,000, and top off at about $18,000. Prices for conference tables with epoxy resin rivers and epoxy-filled CNC logos or scenes will cost more.

The epoxy resin and wood river tables for sale online here are the highest quality river tables handcrafted by Chagrin Valley Custom Furniture in Ohio. Prices for river tables start at $2,100. Epoxy waterfall table prices start at $2,100. River dining tables prices start at $4,500.

-

Buy An Epoxy Resin & Wood River Table Online

-

Epoxy Table Prices From $1,900

-

Custom Made By Chagrin Valley Custom Furniture

-

Live Edge Tables For Sale

-

Epoxy Waterfall Tables $1,900

-

High-End Epoxy River Dining Table $4,500

-

Handcrafted By Chagrin Valley Custom Furniture In Ohio

-

Buy Walnut Rive Coffee Table $2,400

-

River Table With Seashells $5,300

-

Epoxy Tables & River Tables For Sale Online At Chagrin Valley Custom Furniture

-

The Highest Quality Custom Made Resin And Wood Tables Are Handcrafted By CVCF

Here Is How We Do It

We make every table and piece of furniture differently because we do exactly what our customers want. Of course we make suggestions and give advice, but before we start building a new river table or furnishing, we know just what our client is looking for. Sure it takes a little technology and drafting expertise to make this happen remotely. But, as luck would have it, most people have a really smart phone and a computer these days, and we know how to design and build completely custom furnishings, so it works out alright.

Our one-of-a-kind approach to building heirloom quality furniture is rare in the United States these days – but that suits us. Sure, there are thousands of individual river table builders on Etsy you can choose from, but CVCF is a real team of woodworkers with many years of shared experience. This is our day job. Sometimes it is our night and weekend job as well. We take it seriously. We make, deliver and install some of the highest quality river tables in the entire United States.

We are veteran carpenters and young woodworkers who love building stuff. We never get bored handcrafting really high quality, built-to-last, high end custom furniture for people that appreciate the old-fashioned approach to customer service. We don’t try to take on more projects than we can handle to make more money because we don’t want to be rushed. We like to take our time and do it right.

Most of the river tables we make are for discerning customers who want a really high quality table or piece of furniture. If you are looking for a really inexpensive river table, CVCF is probably not your best option. We build river tables for fashionable family dining rooms, resort cafes, luxury hotel lobbies, restaurant chains, lodges, cabins, outdoor patios and corporate boardrooms. The time we take just to put the multiple coats of finish on the tables we build would surprise you. Our dynamic team takes their time building what our customers want because they deserve the extra effort. When prompted, project manager Shel Myeroff will suggest the highest quality woods, resins, table legs and finishes, because some of our clients are looking for the best of the best.

Buy a custom made epoxy resin and wood table made with your vinyl decal, favorite sports team emblem, logo, stickers, college mascot or personal family pictures embedded under the epoxy in the table top.

We are a company that specializes and focuses on manufacturing extremely high quality furniture for customers in the U.S. because our clients are the type of people that value old-fashioned impeccable craftsmanship and quality over price. We blend art, design and woodworking to create stunning, sturdy, visually appealing and long-lasting heirloom furniture that will be passed down from generation to generation.

Our veteran woodworkers and experienced metalsmiths welcome all kinds of imaginative design projects. Every day, we look forward to receiving amazing river table design ideas from amazing Americans that want a really great river table custom made for their new home, office, conference room, boardroom room, bar, business, school, RV, boat or yacht.

Some of the favorite types of river tables we handcraft are fancy (and trendy) live edge wood and epoxy resin river dining tables that have glass, pebbles, river rocks, gems, crystals, sea shells or stones embedded into a meandering blue resin river.

Large river conference tables that seat 8-12 people with LED lights are a lot of fun to make as well. See pictures shown below of custom river tables we have “co-designed” with our customers or peruse a photo gallery. CVCF custom furniture designers and makers recommend the best types of wood for epoxy tables and river tables such as 2″ thick black walnut live edge wood slabs.

Custom Epoxy Resin Office And Computer Desks For Sale

Chagrin Valley Custom Furniture specializes in custom live edge epoxy resin and wood river desks and workstations, including ergonomic adjustable height desks. In these times with so many people working out of their homes, it is important to have a workspace that works for you while offering you comfort and peace of mind. Since you get to custom design your own furniture for CVCF to build, you are assured of getting a desk or workstation that fits your space, matches your décor, fulfills your vision, and elevates the character of your home office. These custom river desks and workstations are ideal for home offices, places of business, hotels, and for the staff at restaurants, bars, and commercial developments.

Prices for our custom built epoxy resin and wood desks range from $3,000 to $6,000 based on the type of wood, desk features and desk size. Ergonomically designed height adjustable river desks will generally cost more, based on the features you choose. We can make straight or L-shaped configurations, add shelves, computer and electronics hookups – whatever you want! It’s your desk and your design.

Custom Live Edge Furniture For Sale

CVCF builds live edge furniture, live edge dining and conference tables using 2″ thick black walnut slabs. Black walnut wood is a very hard strong and straight dark brown wood that is shock resistant. Black walnut timber is popular because the fine-grained heartwood is excellent for making fine furniture. Cambia wood, (thermally modified to increase durability) is another dark wood that CVCF uses to make custom live edge conference tables. CVCF uses black walnut and cambia wood (poplar and red oak) to craft handmade live edge conference tables that can be 10′, 11′, 12′, 16′ or 32′ in length. A common width for a black walnut conference table is 4′.

The Japanese-American architect George Nakashima, winner of the Institute of Architects’ Gold Craftsmanship Medal, favored black walnut slabs and used the natural edges of the wood as part of his finished pieces of furniture to emphasize and celebrate nature’s imperfections.

Custom Made Rustic Furniture For Sale

CVCF also specializes in rustic furniture—many pieces are made from reclaimed barn wood—and live-edge pieces that incorporate the natural edge of the wood into the look. CVCF also handcrafts custom made live edge epoxy resin river headboards and live edge wood beds for customers all across the United States. We won’t bore you by explaining the wood joinery techniques used by the CVCF craftsmen but they include dovetails, wedged-through tenons, wood-to-wood joinery, pegged mortises and tenons and half-laps. The CVCF woodworkers and carpenters use these techniques to make high quality river tables, custom cabinets and custom furniture.

Many of these pieces also incorporate a waterfall (or riverbed), which is a technique using epoxy resin to create a colorful accent. Chagrin Valley Custom Furniture’s critically acclaimed epoxy resin furniture has become a sought-for name in modern furniture, finding its place in businesses, restaurants, and homes across the United States. PRWeb is among many of the news syndicates that have brought national attention to CVCF in the wake of their growing popularity. Learn more about epoxy resin wood furniture for sale here, or about Chagrin Valley Custom Furniture’s presence in homes and businesses across the USA by clicking the button below.

CVCF uses decorative layered resin art and natural wood slabs to build one of the hottest types of furniture on the market in 2023 – ‘Wood & Resin Ocean Coast Tables‘. CVCF woodworkers and resin specialists use an epoxy resin technique to make it look as if ocean waves are crashing. CVCF sells ocean wave resin tables, resin wave tables, beach scene epoxy tables, moving ocean tables, epoxy resin ocean art, ocean epoxy tables, live edge ocean shore coffee tables, ocean resin coffee tables, ocean surf coffee tables, wood and resin ocean coast tables, resin beach tables and custom epoxy resin “Ocean Tables” that capture ocean waves crashing on a beach. CVCF makes coffee tables with ocean waves that move. CVCF is a U.S. based ocean resin table manufacturer that specializes in combining decorative layered resin art with live edge wood slabs, reclaimed wood and walnut slabs.

These ‘Ocean Tables‘ are one of the most trendy pieces of furniture on the market in 2023. See pictures of an amazing custom handmade live edge epoxy resin ocean table that CVCF custom built. Watch a step-by-step guide to making epoxy resin ocean tables.

CVCF uses blue and white epoxy resins to build ‘Ocean Tables’ that capture the idea of moving tides and waves crashing on a shoreline. ”Ocean Tables’ can also be made using epoxy resin and concrete (concrete looks like sand). Because many of CVCF’s customers in the U.S. have been inspired by our river tables, we are now taking orders for ‘Ocean Tables’ and “Canyon Tables’. Watch a YouTube tutorial video to learn different resin techniques to create epoxy resin art ocean waves and beach inspired seascapes in wood surfaces. Submit your design idea for a custom ‘Ocean Table’ here to get a price quote or call 440-591-5511.

How Does CVCF Build ‘Canyon Tables’ or ‘Canyon River Tables’?

Canyons are beautiful. A river runs through the beautiful ‘Canyon Tables' custom built by CVCF. ‘Canyon Tables’ are a style of river tables that use a wood slab layering effect to simulate a river running through a gorge. The stunning one-of-a-kind ‘Canyon Tables” custom built by CVCF simulate a deep gorge with a river flowing through it. These pieces of functional art combine the elegance and tranquility of running water with the drama and depth showcased canyons. ‘Canyon River Tables’ are made from solid natural wood, live edge wood slabs, glass, epoxy resin and normally come with custom steel legs and bases. CVCF uses two distinct pieces of live edge wood to surround an epoxy resin river that suggests a river running through a canyon. CVCF sells Canyon River Tables to customers throughout the U.S. and ships them to all 50 states.

The handcrafted Canyon Tables” built by CVCF in Cleveland, Ohio showcase a deep cleft in the center of the dining table, coffee table, side table, kitchen table, countertop or conference table. Our woodworkers create a weathered and erosive look caused by the river in the table by using our fine woodworking skills and epoxy resin expertise. We take river tables a step further by making the epoxy resin rivers look like they are cutting through the underlying surfaces of the gorgeous wood slabs. Here is an example of a ‘Grand Canyon River Table’. CVCF builds ‘Canyon River Tables’ using cherry wood, black walnut, oak, hickory and spalted maple. CVCF also showcases the beauty of running water by building custom live edge wood and epoxy resin waterfall tables and waterfall desks. Submit your design idea for a custom ‘Canyon River Table’ here to get a price quote or call 440-591-5511.

How Much Do Custom Conference Tables Cost?

Price Ranges For Custom Conference Tables For Sale At Chagrin Valley Custom Furniture

Standard Custom Conference Table Prices Start At $4,500+ Delivery

Types Include:

-

Industrial Conference Tables: From $4,500+ Delivery & Crating Costs

-

Live Edge Conference Tables: From $4,500+ Delivery & Crating Costs

-

Natural & Reclaimed Wood Conference Tables: From $4,500+ Delivery & Crating Costs

-

Modern Conference Tables: From $4,500+ Delivery & Crating Costs

Prices For A Custom Made Wood And Steel Conference Table With A CNC Designed And Engraved Brand Or Logo

-

Seating Capacity For 6: From $5,800+ Delivery & Crating Costs

-

Seating Capacity For 8: From $8,000+ Delivery & Crating Costs

-

Seating Capacity For 10: From $10,000+ Delivery & Crating Costs

-

Seating Capacity For 12: From $12,000+ Delivery & Crating Costs

Prices For A Custom Made Wood And Steel Conference Table With An Epoxy Resin River

-

Seating Capacity For 6: From $5,600+ Delivery & Crating Costs

-

Seating Capacity For 8: From $6,500+ Delivery & Crating Costs

-

Seating Capacity For 10: From $7,800+ Delivery & Crating Costs

-

Seating Capacity For 12: From $9,000+ Delivery & Crating Costs

Prices For A Custom Made Wood And Steel Conference Table With An Epoxy Resin River And A CNC Designed And Engraved Epoxy Resin Logo

-

Seating Capacity For 6: From $6,800+ Delivery & Crating Costs

-

Seating Capacity For 8: From $8,800+ Delivery & Crating Costs

-

Seating Capacity For 10: From $10,800+ Delivery & Crating Costs

-

Seating Capacity For 12: From $12,800+ Delivery & Crating Costs

Types Or River Tables We Sell

-

River Dining Tables For Sale

-

Epoxy River Tables For Sale

-

Stunning Live Edge River Tables For Sale

-

River Coffee Tables For Sale

-

Waterfall Tables

-

River Tables With 3D Fish

-

River Tables Handcrafted Using Bio-Based Epoxy Resin

-

Live Edge River Tables That Glow In The Dark

-

Epoxy Wood Tables For Sale

-

Console Table With Epoxy Resin Inlays

-

Unique Custom Made “A River Runs Through It” Coffee Tables For Sale

-

Wood And Resin Dining Tables For Sale

-

Round River Tables For Sale

-

Live Edge And Epoxy Resin River Desks With Extensive Customization

-

Soothing Natural Stone And Resin Coffee Tables

-

River Tables That Feature Facsimiles Actual U.S. Rivers Such As The Missouri, Mississippi, Ohio, Colorado and Hudson River Embedded In The Wood Slab

-

Handmade Custom River Tables With Facsimiles Of USA Lakes Made With Epoxy Resin Such as Lake Michigan, Lake Erie, Lake Ontario, Lake Superior And Lake Huron

-

Custom River Tables That Use Epoxy Resin Colors Featured In College Team Logos Such As The Ohio State University Buckeyes Colors Of Scarlet, Grey, White And Black

Share Your Design Idea With Shel To Get Started

Walnut river tables are awesome. Black walnut river tables are very popular in the USA in 2019 because the kiln dried dark-colored, straight grained true heartwood contrasts so vividly with a blue epoxy resin river. The craftsmen at Chagrin Valley Custom Furniture love to make custom designed tables from walnut wood slabs because it is so darn beautiful and workable. CVCF loves to use black walnut wood for woodworking projects. Although it is not as readily available in the USA, CVCF has a few secret sources for this cherished wood. American Black Walnut is the darling of the CVCF craftsmen. CVCF designs, handcrafts ships, delivers and assembles black walnut river tables, epoxy resin furniture and live edge waterfall benches for customers across the USA. Prices for small walnut river coffee tables start at $825. Simply provide CVCF with your walnut river table design requirements to receive a quote for your woodworking project.

Popular Epoxy Resin Colors For Custom Made River Tables, Custom Epoxy Resin Desks And Custom Live Edge Desks For Sale

-

Red

-

Black

-

Gray

-

Green

-

Blue

-

Purple

-

Dark Blue

-

Turquoise

-

Light Blue

-

Sky Blue

-

Azure

-

Navy

-

Teal

-

Gray With White

-

Lava

-

Maroon

-

Copper

-

Saddle

-

Crimson

-

Onyx

-

Glacier

-

Black And White

-

Emerald

-

Clear

-

Dark Blue-Green

The Process

When creating a river table, a clear epoxy resin is poured into a rectangular or custom mold with the target live edge slabs in place. Additional resin mixed with the chosen color or colors is then added to meet the specifications of the project, and then any other objects are set – such as gold flakes or crystals. Between pours, the epoxy is stirred within the form to prevent any settling of color or the creation of bubbles.

Then we let the epoxy cure and harden and remove the mold. Next, we sand down any imperfections. The wood is finally sprayed or finished with the desired top coating for durability, aesthetics, and/or longevity.

Non-Tabletop Furniture With Epoxy Resin “River” Designs

We also sell types of furniture with epoxy resin designs that utilize live edge wood, but are not to be used as a tabletop or to attach a steel base. Seen below, we built this live edge headboard for a client looking for a matching frame and end tables with our signature blue river design. Any kind of luxury, live edge or rustic furniture with a natural edge can be fitted into a mold and poured with the color of epoxy resin you’re looking for. This can include live edge headboards, chairs, benches, cabinets, buffets, cabinet doors, display cases, entertainment centers, mantels, shelves and more. Seen below are two examples of a live edge walnut headboard and bedroom set, as well as a live edge walnut bench with epoxy resin poured and cured in the final product. You can contract pieces like these from anywhere in the United States through our customer service-oriented remote design process. Start by contacting us.

River Table Prices

Pricing a river table design varies widely, depending on wood type, size, the chosen legs/base, and the overall complexity of the project. River tables can be made for tables of any purpose, including coffee tables, side tables, dining room tables, and conference room tables.

So Who Invented The River Table?

From time to time, the river table builders at CVCV get asked, “Who invented the river table?” Although the talented Washington-based artist and furniture-maker, Greg Klassen trademarked the word “River” in regards to furniture design, he certainly did not invent the river table or the use of epoxy resin in artistic furniture or the concept of resin casting. Epoxy, and thermosetting resins, first became a household word in the 1960s, when a new breed of super-strong adhesives started to appear in local hardware stores. Its extensive use dates back as far as the 1940s.

Natural resins have been used since as early as the days of ancient Egypt, and more extensively in the 1200’s AD by the Mongols. The Mongols invented the world’s first composite (made of multiple components) bow, which were bound together with natural pine resin. Many historians suggest that these were the most formidable weapons in the world until firearms emerged a couple centuries later. It was also a long-time material for ship-builders, as it was an excellent sealant and waterproofing agent on wooden vessels.

Epoxy resin, mixed with pigment, may be used as a painting medium, by pouring layers on top of each other to form a complete picture. It is also used in jewelry, as a doming resin for decorations and labels, and in decoupage type applications for art, wood countertops, and custom river tables handcrafted by CVCF.

Over, seventy-five years ago, in a small lab in Louisville, Kentucky, Dr. Sylvan O. Greenlee invented a material that may have seemed ordinary to most, but he knew that he had just discovered a material that would enable the future. That landmark discovery was liquid epoxy resin.

Learn More About Epoxy Resins From Wikipedia

Epoxy is either any of the basic components or the cured end products of epoxy resins, as well as a colloquial name for the epoxide functional group. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. Condensation of epoxides and amines was first reported and patented by Paul Schlack of Germany in 1934. Claims of discovery of bisphenol-A-based epoxy resins include Pierre Castan in 1943. Castan’s work was licensed by Ciba, Ltd. of Switzerland, which went on to become one of the three major epoxy resin producers worldwide. Ciba’s epoxy business was spun off as Vantico in the late 1990s, which was subsequently sold in 2003 and became the Advanced Materials business unit of Huntsman Corporation of the United States. In 1946, Sylvan Greenlee, working for the Devoe & Raynolds Company, patented resin derived from bisphenol-A and epichlorohydrin. Devoe & Raynolds, which was active in the early days of the epoxy resin industry, was sold to Shell Chemical; the division involved in this work was eventually sold, and via a series of other corporate transactions is now part of Hexion Inc.

Epoxy adhesives are a major part of the class of adhesives called “structural adhesives” or “engineering adhesives” (that includes polyurethane, acrylic, cyanoacrylate, and other chemistries.) These high-performance adhesives are used in the construction of aircraft, automobiles, bicycles, boats, golf clubs, skis, snowboards, and other applications where high strength bonds are required. Epoxy adhesives can be developed to suit almost any application. They can be used as adhesives for wood, metal, glass, stone, and some plastics. They can be made flexible or rigid, transparent or opaque/colored, fast setting or slow setting. Epoxy adhesives are better in heat and chemical resistance than other common adhesives. In general, epoxy adhesives cured with heat will be more heat- and chemical-resistant than those cured at room temperature. The strength of epoxy adhesives is degraded at temperatures above 350 °F (177 °C).