Custom Home Or Office Desks

Custom Desks For Any Professional Setting

CVCF designs and builds unique, made-to-order desks for clients throughout the US. When you commission a custom wooden desk from CVCF, you choose the shape, size, wood, materials, epoxy resin colors and design features. We then take all of your ideas and preferences and expertly craft your one-of-a-kind piece.

Whether you’re looking for custom branded live edge desks for your business, or a unique desk to show your personality at home, we’re up to the task! We can create adjustable height sit/stand desks, L-shaped desks, corner desks, and more.

Customization Options

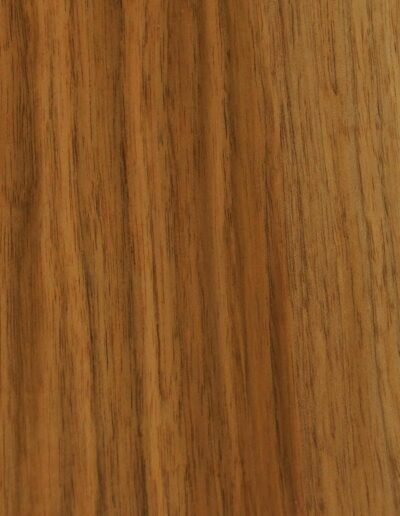

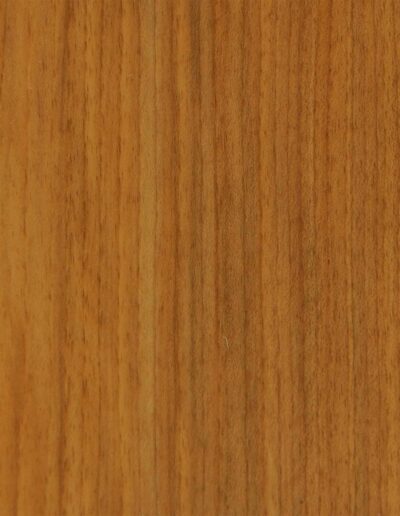

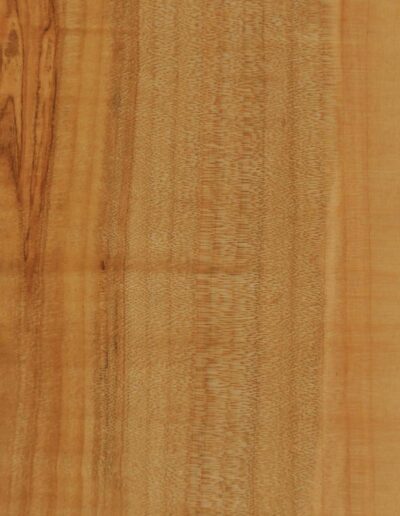

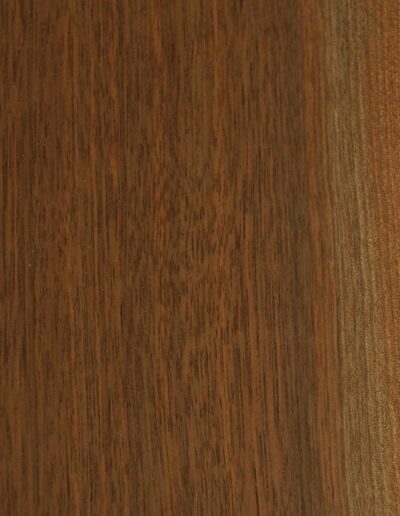

- The shape, size, thickness, and wood species of your desk. We have access to any hardwood out there; our most popular options include walnut, cherry, maple, elm, oak, hickory, and mahogany. Woods are available in live edge varieties and straight cut.

- Resin rivers or other resin features, from clear to swirled blue to solid black resin. Anything you’re looking for, we can provide.

- Would you like a local landmark or design CNC engraved into the desktop? Our facility has only the most cutting edge equipment, and we regularly built for clients who want a local topographical map feature running through their design. We are one of the only custom furniture facilities that can make this happen in-house.

- Adjustable-height functionality to make your desk into a standing desk. Special legs and eletrical components can be attached which can change the height of your desktop at the push of a button. Remote included.

- LED backlighting to illuminate your resin designs from below.

Desks For Any Purpose

Live edge river desks and solid, hardwood desks are just the tip of the iceberg when it comes to our customization capabilities. When ordering from CVCF, the goal is to make your dream desk a reality. The design options are endless.

- Sit-Stand Desks – With more people working from home than ever before, it’s important to stay both productive and comfortable while on the job. CVCF offers desks with adjustable height functionality, also known as sit-stand desks. These desks are built with bases you can raise to standing height and lower back down to standard height.

- Home Office Desks – CVCF can customize your home office desk to fit your needs. Looking for a desk with storage? We can build pencil drawers, attach file holders, and make a small cabinet or shelves to fit your piece. Do you have a unique space and standard-built desks just don’t fit properly? CVCF has made L-shaped and U-shaped desks of numerous sizes to fit any space.

- Gaming Desks – Whether you game as a hobby or as a full-time job, CVCF can make your custom gaming desk work for you. We have add-ons such as cable management systems, monitor mounts and stands, powerboxes, cubbies for storage, and extra hooks/arms for hanging headsets. LED lights installed in your desk are also a great way to add atmosphere while you play.

- Executive Desks – Make a statement with your desk by ordering from CVCF. We have countless wood options and resin colors to match your company’s branding. Keep your desk organized by adding grommets and wire management.

If you have a request for customization and don’t see it listed, feel free to reach out with questions. You can contact zach@chagrinvalleycustomfurniture.com, or give us a call at 440-591-5511.

Explore Wood Species Options for Your Solid Wood Desk

Chagrin Valley Custom furniture is a custom office furniture manufacturer. Below are some (but not all) of the wood species available for wood slab desks. You can also send your own wood slabs for production, or ask our team for the available selection of exotic woods, which includes redwood, tiger maple, purple heart, and more.

Explore Live Edge Desk Leg and Base Options

Bases and legs are also customized and custom made to your tastes and desires. We currently have two “tiers” of base styles – standard and specialty. Within these groups, each base style is custom made to properly support the dimensions and aesthetic of your desktop.

You can also have your legs/base custom made. Just send your concept, we will refine it and send 3D models for your approval. Then, it’s built. Forged and welded from scratch.

Epoxy Desk FAQs

How Long Do Epoxy Tables Last?

The lifespan of an epoxy resin table can vary significantly based on several factors, including the quality of construction, usage, care, and the environmental conditions to which it’s exposed. In general, well-made epoxy tables can last for generations. Here are some factors to consider:

- Quality of Construction: High-quality craftsmanship and materials contribute to the longevity of an epoxy table. Proper sealing and bonding of the epoxy to the wood or other substrate are crucial.

- Usage: How the table is used can impact its lifespan. Tables used for light to moderate everyday activities tend to last longer than those subjected to heavy use or abuse.

- Care and maintenance: Regular cleaning and maintenance, such as avoiding excessive heat exposure and cleaning with mild, non-abrasive products, can extend the table’s life.

- Environmental factors: Exposure to extreme temperature fluctuations, humidity, or direct sunlight can affect the longevity of an epoxy table. Ideally, these tables should be used in controlled indoor environments.

- Quality of epoxy resin: The quality and type of epoxy resin used in the table’s construction can also influence its durability. High-quality, UV-resistant epoxy resins are more likely to withstand environmental factors.

How Do Epoxy Tables Hold Up?

Epoxy tables can last for generations. They are as durable as any other material if properly cared for. They hold up admirably when constructed with high-quality epoxy resin and proper sealing techniques. Their hard and durable surfaces resist scratches and everyday wear, making them suitable for long-lasting use. Regular maintenance with mild, non-abrasive cleaning products, along with safeguarding the table from extreme temperatures and physical impact, can help maintain their appearance and longevity. However, epoxy tables are best suited for controlled indoor environments, as exposure to extreme temperature fluctuations, direct sunlight, or high humidity may affect the durability of the wood. The craftsmanship and quality of materials used in the construction of epoxy tables also play a significant role in their durability, ensuring they continue to be both functional and visually appealing for years to come.

Is Making Epoxy Tables Hard?

Making epoxy tables well, and with the level of quality CVCF customers require, is extremely challenging due to various factors. Simple mistakes can be costly. The level of difficulty is often tied to the complexity of the table’s design, with simple designs being more accessible for DIY enthusiasts and complex designs demanding advanced skills. Working with epoxy resin requires a good understanding of its properties, mixing ratios, curing times, and potential issues like air bubbles. Precision and attention to detail are essential, as any imperfections in the wood or epoxy application can affect the result. Safety precautions, such as proper ventilation and protective gear, are necessary when handling epoxy resin. Environmental factors can also come into play, affecting the curing process.

What Is The Best Wood For an Epoxy Table?

The selection of the best wood for an epoxy table hinges on various factors, including design preferences and desired aesthetics. Several wood options are commonly favored for creating epoxy tables due to their durability and visual appeal. Walnut is often chosen for its rich, dark color and unique grain patterns, offering a luxurious and timeless look. Maple provides a light, modern appearance with a clean, uniform grain. Cherry wood develops an elegant reddish-brown hue over time and features a warm grain pattern, making it suitable for a classic and refined appearance. Ash, with its straight grain and light color, lends itself to versatile and contemporary designs. Ultimately, the choice of the best wood for your epoxy table should align with your specific aesthetic vision and the availability of materials, considering the wood’s moisture content and your woodworking skills for the best results.

Which Wood Is Best For a Live Edge Table?

Selecting the best wood for a live edge table is a matter of aligning the material with your design preferences and the specific characteristics you want in the finished piece. The color, grain patterns, distressed look, and curvature of the live edge are elements to consider. We suggest removing the bark, which can be rough to the touch and prone to flaking. Live edge tables are prized for their natural, untrimmed edge, which showcases the wood’s unique features. Several wood options are commonly chosen for this purpose. Walnut, with its rich, dark color and striking grain patterns, adds an element of luxury and elegance. Maple provides a lighter, more contemporary look with a uniform grain. Cherry wood, which matures to a warm reddish-brown hue and exhibits a beautiful grain pattern, lends a classic and refined aesthetic. Redwood and cedar are sought after for their distinct coloring and durability, ideal for rustic or natural-themed designs. Ultimately, the best wood for your live edge table depends on your preferred style, the availability of materials, and the overall aesthetic you wish to achieve. The best manufacturers will ensure that the wood slab is properly dried over a period of years, not months, and prepared to prevent long-term issues like warping or cracking.

How Much Does an L-Shaped Desk Cost?

- Custom Desks: Custom-made L-shaped desks, designed to your specifications with premium materials, can vary widely in price, often starting at $4,000 and going up significantly, depending on the materials and the complexity of the design. Custom desk makers can offer and strategically place the accessories you need as well, including monitor stands, keyboard trays, wire management, and grommets for wires.

- High-End Desks: High-quality L-shaped desks made of solid wood, premium materials, and intricate designs can cost anywhere from $3,000 to tens of thousands of dollars, depending on the brand and craftsmanship.

- Budget Desks: Basic L-shaped desks made of budget-friendly materials like particle board or laminate can cost as low as $100 to $200.

- Mid-Range Desks: L-shaped desks made of better-quality materials like MDF or solid wood, with improved finishes and design, typically range from $200 to $500.

Is an L-Shaped Desk Worth It?

Whether an L-shaped desk is worth the expense and space it takes up depends on your individual needs and how you plan to use the desk. L-shaped desks are particularly valuable for those looking to optimize space, especially in corner or wall setups, as they provide ample workspace for various tasks. Take into account how much time you spend at your desk and evaluate the value of a desk designed for your needs. These desks can enhance productivity by offering separate areas for different activities, making it easier to stay organized and efficient. The ergonomic configuration of an L-shaped desk can contribute to comfort during work or study sessions. Additionally, their modern and professional appearance can be aesthetically pleasing. L-shaped desks are versatile, accommodating a range of activities, from work and studying to gaming and creative projects.

If you spend a lot of time at your desk — and many of us do — a custom desk is a worthwhile investment. Custom furniture manufacturers take not only your aesthetic preferences and practical needs into consideration but ergonomics as well, such as your height, preferred keyboard placement, required legroom, sit-stand options, and more — even accommodations for a treadmill while you work. The decision to invest in an L-shaped desk ultimately depends on your specific requirements, available space, and budget.

What Size Is a Standard L-Shaped Desk?

There really is no standard except the depth. The smallest depth is typically 30” deep as a standard. The length of the shorter side of the “L” can range from around 48 inches (4 feet) to 60 inches (5 feet) or more. The longer side of the “L” typically ranges from about 60 inches (5 feet) to 72 inches (6 feet) or more. Custom L-shaped desks can fit both your work area and the room you are working in. CVCF creates sit-stand desks to custom heights and dimensions adjusted for the client. CVCF also builds custom treadmill desks. The largest custom desk built by Cuyahoga Valley Custom Furniture was a very large 10’ x 10’ x 44” deep. We take elements like custom height and leg room for maximum comfort. We also offer custom pencil drawers, monitor stands, keyboard trays, power supply, wire management and grommets for wires.